Technologies

Tangible Redefining the Contact Lens Experience:

An Interview with Brandon Felkins of Tangible Science

What is the need Tangible Science seeks to address?

Initially, we started thinking about a way to help patients who suffer from contact lens-induced dry eyes, a condition that affects more than half of all contact lens wearers.But, over time, our focus has become broader. Our mission today is to create the most comfortable contact lens-wearing experience possible.

"Our mission today is to create the most comfortable contact lens-wearing experience possible."

What key insight was most important to guiding the design of your solution?

The key insight for the product came from taking a step back and really looking at the design of contact lenses, specifically the material properties, with a fresh pair of eyes. Up until this point in time, contact lens design had been driven by the big contact lens manufacturers, whose focus had typically been on trying to develop a single lens material that would be easy to manufacture and also great for the patient. But innovating within the constraints of existing manufacturing often led to incremental changes that were subject to tradeoffs between comfort and manufacturability.

Our approach was to look at the problem first and foremost from a more biological perspective to really understand what a ‘perfect lens’ for the patient would look like. Once we understood that, we then focused on figuring out how to make it manufacturable. By freeing ourselves from typical constraints early on, we were able to develop a novel solution.

The core Tangible Science team, Victor McCray, Karen Havenstrite, and Brandon Felkins.

The core Tangible Science team, Victor McCray, Karen Havenstrite, and Brandon Felkins.

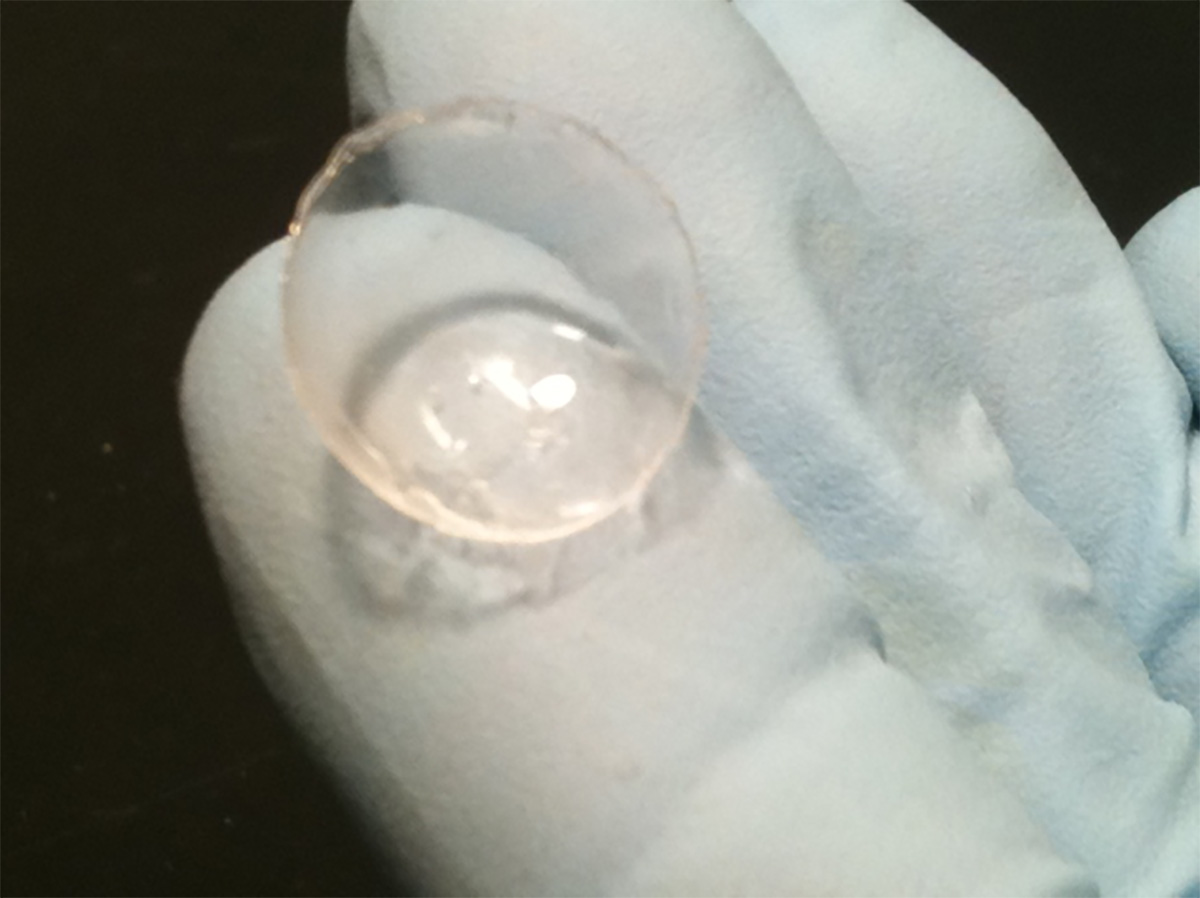

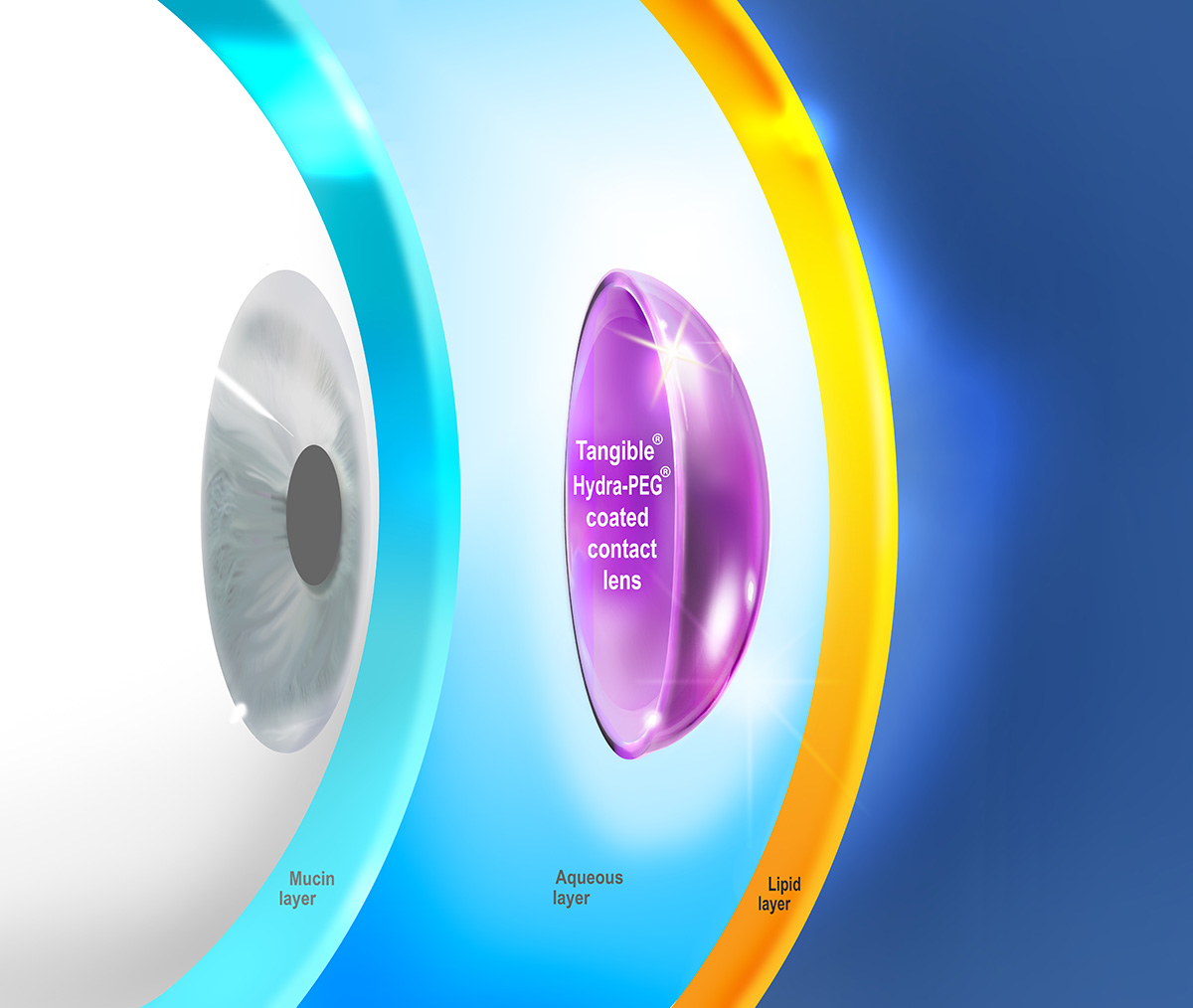

Ultimately, we determined that a ‘perfect’ lens would have surface properties that were decoupled from the properties of the core lens material. Specifically, the lens surface would have a very high water content that would allow the lens to integrate into the ocular environment without disrupting the ocular tear film. Conversely, the lens core would have a low water content that would enable consistent manufacturability, oxygen transmission to the eye, and easy lens handling by the patient, which is how the majority of existing lenses were designed. By decoupling the surface from the core of the lens, we were able to develop a surface coating technology that could be used to ‘shield’ the eye and the tear film from the sub-optimal surface properties of the existing lenses on the market.

How does your solution work?

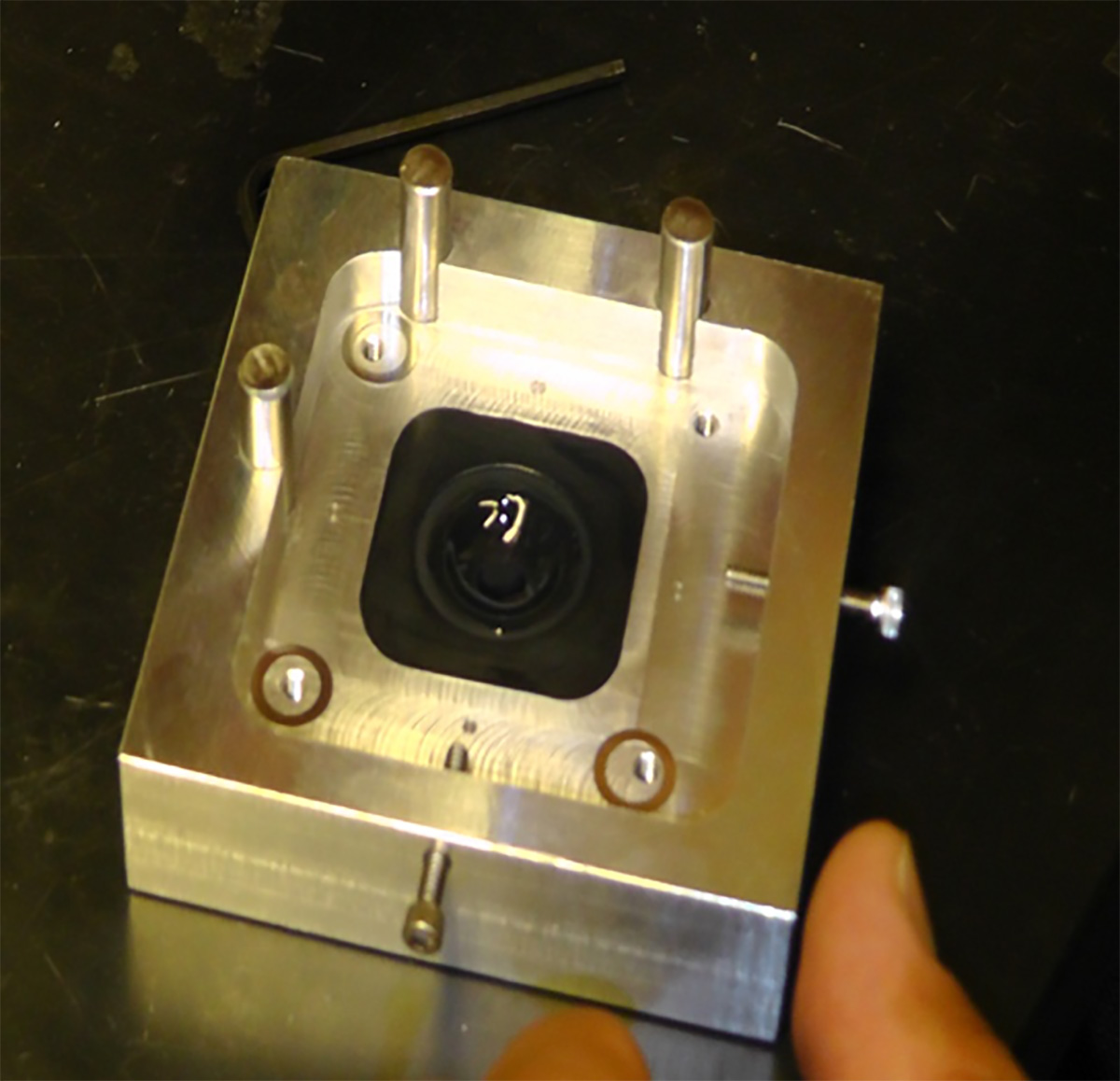

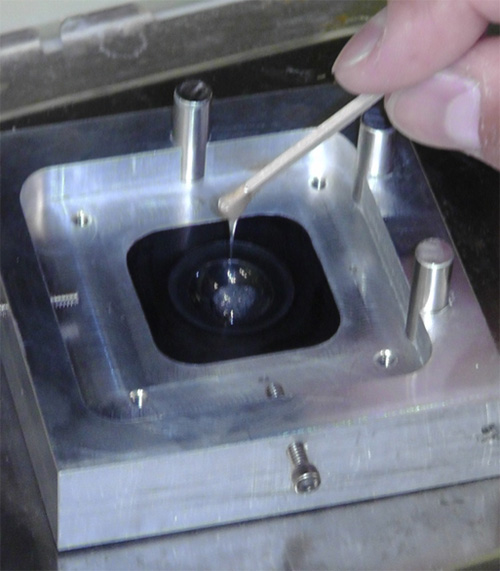

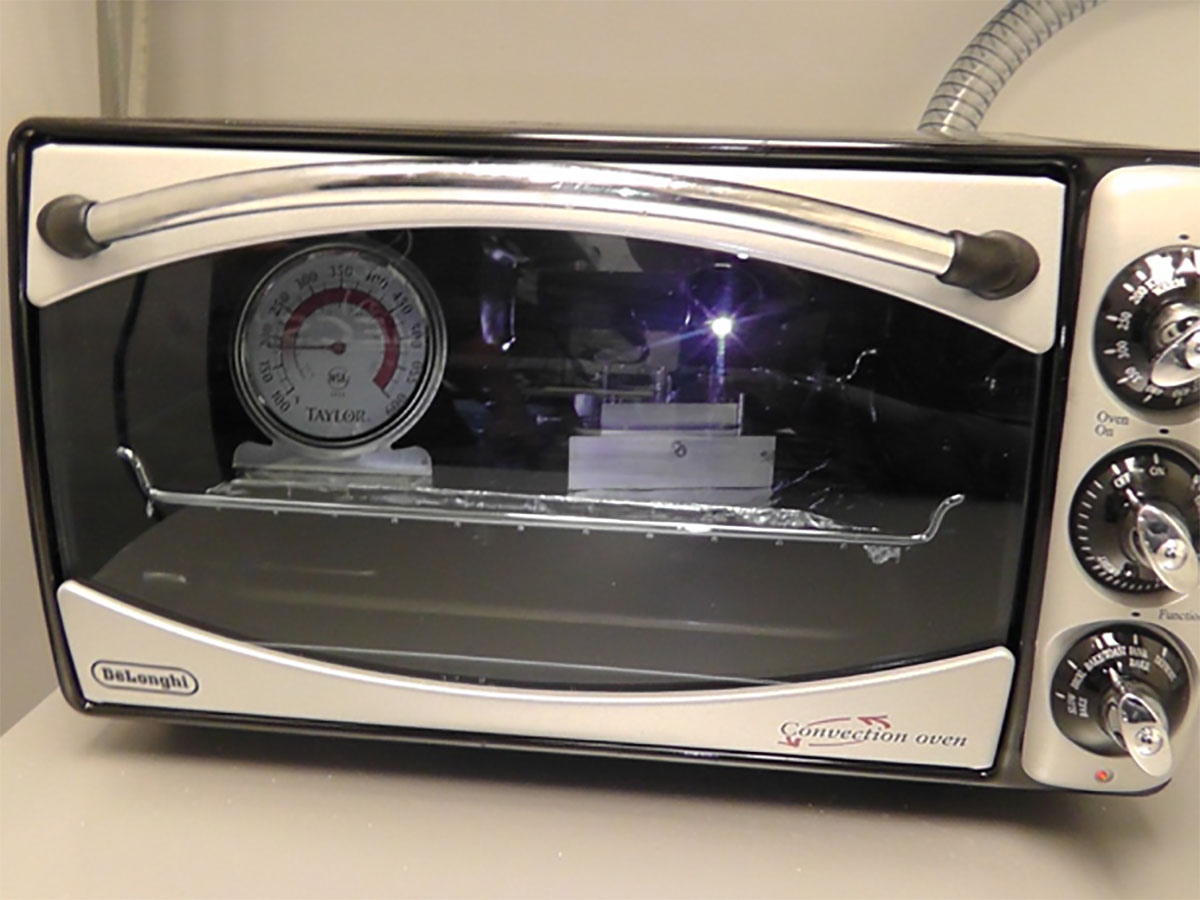

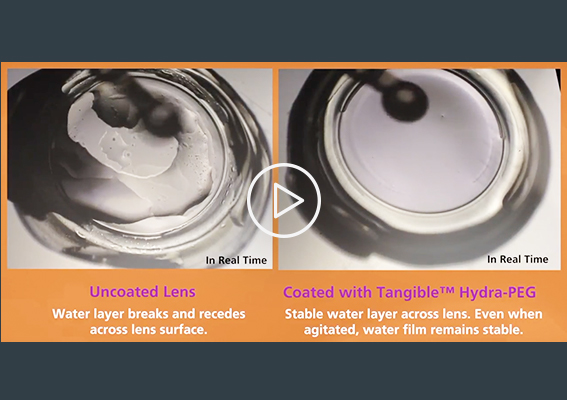

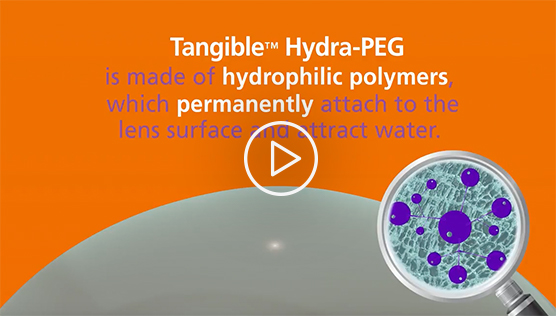

Our core product is a biocompatible polymer coating that enhances the surface properties of the contact lens. The coating increases comfort and performance by making the lens more wettable, slippery, and resistant to deposits and proteins that can stick to its surface and cause fogging. The coating can be applied to any contact lens material at the final stage of manufacturing.

At what stage of development is the solution?

The Tangible Hydra-PEG coating, which is our first commercial product, is initially being used on hard and hybrid contact lenses. We have partnership agreements in place with every major custom contact lens manufacturer in the US, as well as multiple international agreements. So the technology is widely available in the custom contact lens space.

This short promotional video, provided by Tangible Science, illustrates how the Hydra-PEG coating is intended to work (see endorsement disclaimer below.)

This short promotional video, provided by Tangible Science, illustrates how the Hydra-PEG coating is intended to work (see endorsement disclaimer below.)

We’re also expanding into soft lenses. We’ve developed relationships with disposable contact lens manufacturers that are producing a variety of disposable lenses enhanced with our coating technology. Our initial strategy is to partner with existing lens companies in the US to sell and distribute these lenses. The initial commercial product in this space is a daily disposable hydrogel lens that is enhanced by our polymers and is currently being sold to patients via one of our custom lens partners. And we have several others that will be launching soon.

What are your plans for the future?

In parallel with expanding into soft lenses, we have other new products coming out that will serve as companion products to our custom lens coating. The first is Tangible Clean, a daily cleaning and conditioning solution that will be on the market before the end of 2018. The second is Tangible Boost, a monthly refreshing solution to help rebuild the coating on the lens that will become available in 2019.

Tell us about a major obstacle you encountered and how you overcame it.

The coating we’ve developed is visibly clear, and it's similar in its properties to the contact lens material itself. So we faced a big challenge developing testing methods to detect the coating and discern which formulations worked best. We had to develop our own assays to help guide product development because available methods just didn't work for us. And this took a really long time. But the process of refining our measurement techniques actually helped us improve the product. It was a virtuous cycle.

Commercialization of the Tangible Hydra-PEG coating was also tricky. The coating is considered by the FDA to be a “component” rather than a “finished medical device.” Because of this, we technically couldn’t seek regulatory clearance or launch the technology without partnering with the manufacturers of the finished lenses, who would ultimately need to obtain the 510(k) clearances to use the coating in conjunction with their products. This limited the speed at which we could commercialize. The custom contact lens market is highly fragmented with dozens of custom lens labs across the US, and even more around the world that manufacture the custom lenses. Currently, we have partnerships with four contact lens material suppliers and over twenty contact lens manufacturers across the globe, including the US, Europe, Brazil, and New Zealand. And we’re bringing on new lab partners every month. But putting these arrangements into place has been logistically challenging as a small company. And it’s proven to be a lot more work than originally anticipated to maintain quality control and support each of these customers.

"When you're doing your project planning, multiply everything by π."

Reflecting on your experience, what advice do you have for other health technology innovators?

When you’re doing your project planning, multiply everything by π. If you think something’s going to take three months to complete, multiply it by 3.14 and that's the actual time you’ll need to get it done. The same goes for budget planning. It seems to work almost every time!

Brandon Felkins co-founded Tangible Science out of the Biodesign Innovation Fellowship in 2011 with teammate Victor McCray. Karen Havenstrite joined the team as co-founder and CTO shortly thereafter. To learn more, visit the Tangible Science website.

Disclaimer of Endorsement: All references to specific products, companies, or services, including links to external sites, are for educational purposes only and do not constitute or imply an endorsement by the Byers Center for Biodesign or Stanford University.